Special Nailing Required for a Stepped Shear Wall

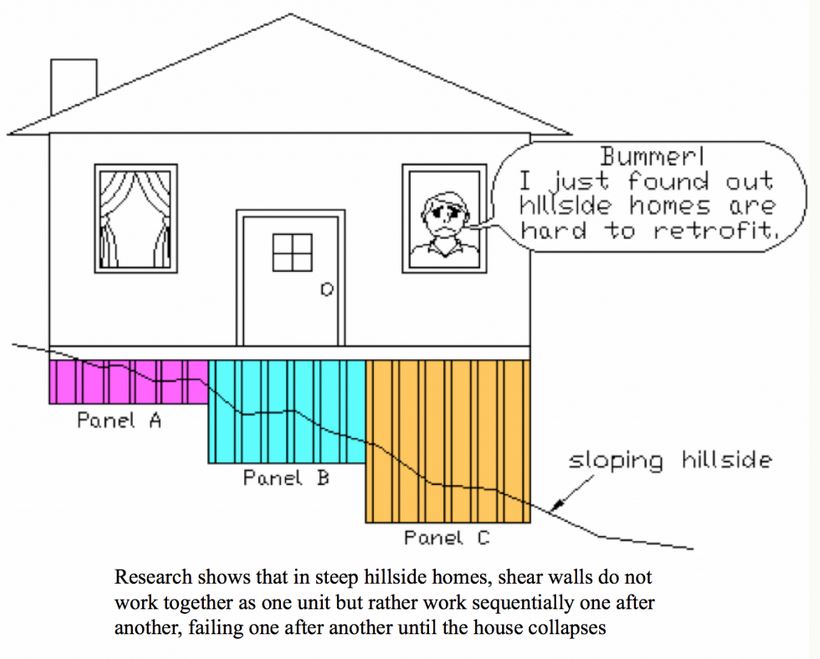

Homes built on a slope have foundations that are stepped and extend down the hill. These foundations must be stepped in contour with the hill as illustrated in the drawing below so the floor can be level. In the Northridge earthquake it was discovered that shear walls built on stepped foundations have peculiar failure characteristics that must be kept in mind.

How do Shear Walls Work?

How do Shear Walls Work?

It is an engineering truism that earthquake forces go into the stiffest element first. Shear walls are like stiff shock absorbers that resist and dissipate earthquake forces before they can damage the house. In a stepped shear wall, this means the shortest segment of the shear wall will fail before the less stiff portions of the shear wall have a chance to react.

The Stiffness Differential

Differing heights in the shear wall crate a stiffness differential. All things being equal in terms of nailing, the short portion of a stepped shear wall is stiffer than the taller portion.

If you look at the shear wall drawing to the right, Panel A is shorter and stiffer than Panel B, and Panel B is shorter and stiffer than Panel C. Based on stiffness, the shear walls will then fail sequentially starting with A, then B, then C.

The Effected on Stepped Shear Walls

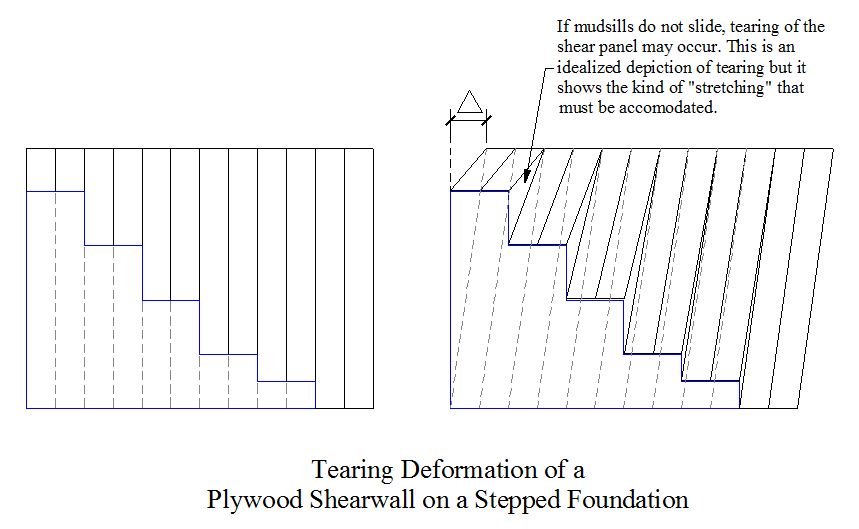

In the drawing below, the triangle represents movement of the floor. If the earthquake moves the floor 6 inches, the shorter shear wall segment will tear at the bolts and become worthless while the taller flexible segment will bend at the top. Once the short shear wall fails, there will be a sequential zippering effect that causes the entire shear wall to fail.

Tearing at the Shear Wall Seams

Another way these shear walls fail is by tearing the plywood at the seams. In these cases, the base of the shear wall remains bolted to the foundation and there is no tearing at the bolt level. However, this failure does make the entire the shear wall ineffective.

How to Address shear wall stiffness differentials

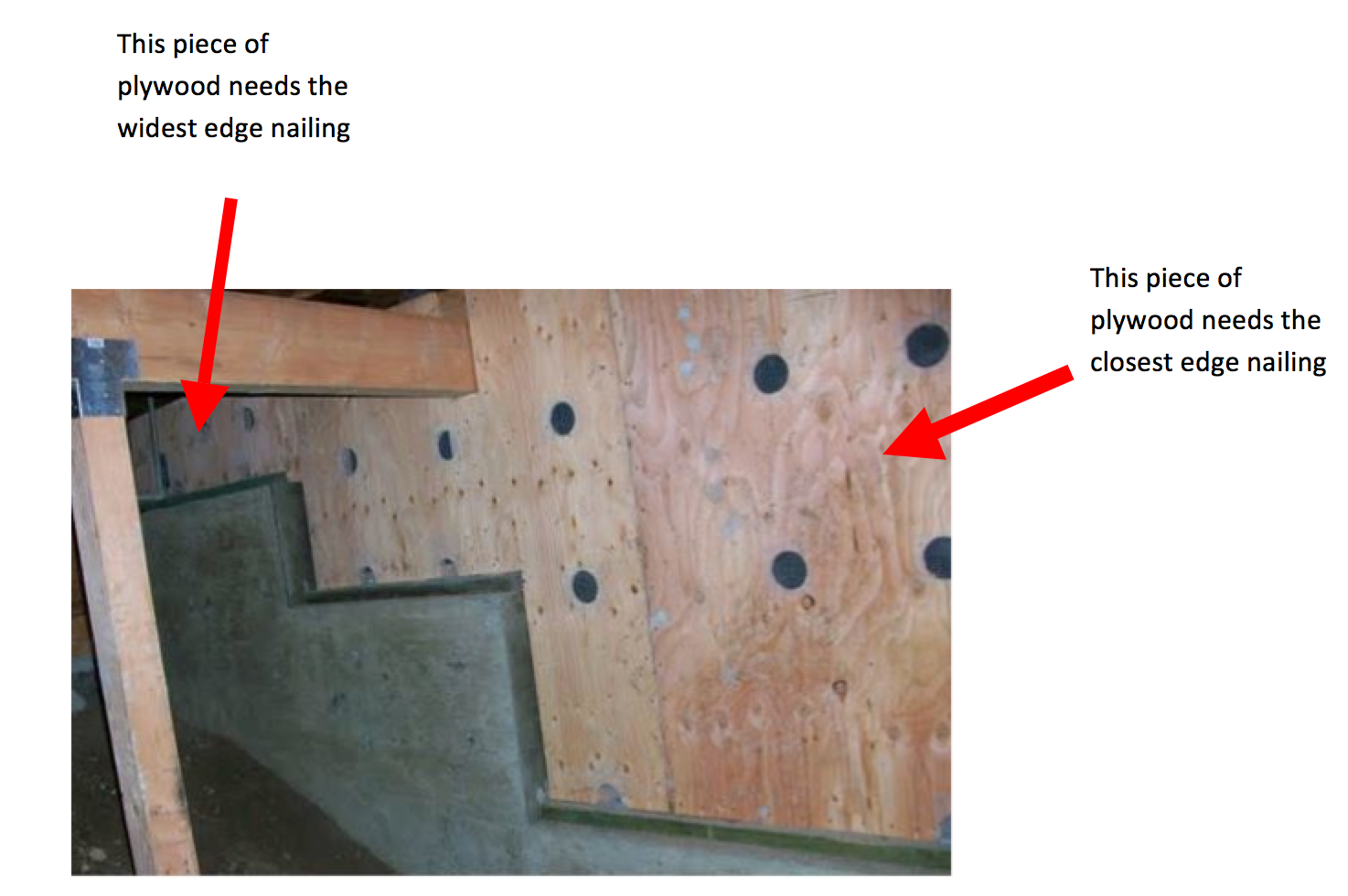

Stiffness in shear walls is also a function of nailing. The closer the nails are spaced on the edge of the plywood, the stiffer the shear wall. Nailing and stiffness are important factors in how much earthquake force a shear wall can resist. If the stepped foundation is very radical, a full hillside home retrofit will be needed. Otherwise, adjusting the nail spacing on the edges will go a long way in making up for this stiffness differential.

The closest you can put nails on the edges of plywood is 2″ apart staggered. Staggered means you snap a chalk line on top of the plywood down the center of the 2 by 4 stud (these are real 2 by 4s, a full 2 inches by 4 inches) so you know exactly where the center of the stud is. Then on each side of the chalk line, drive a nail 4 inches apart. The net is a nail every two inches apart of the edge of the plywood. Remember this is only done on the edges of the plywood.

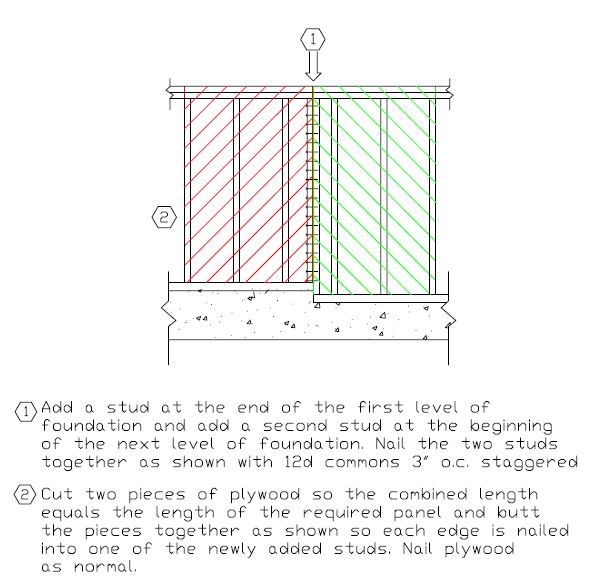

Conventional Shear Wall Construction

Where two pieces of plywood come together at a vertical seam, you will need to attach an additional vertical 2 by 4 to the existing 2 by 4s so each 2 by 4 has something to nail to. For high-capacity shear walls, the building code requires 3 by studs at all seams, but it is just as good to nail two 2 by 4s together. In the illustration below, the plywood is nailed 3 inches apart on the edges rather than 2 inches apart. It just depends on how strong you want your shear wall. To put it another way, as expressed by a very experienced structural engineer:

The interconnection of the 2-2×4’s must have the same shear capacity as the plywood-to-stud capacity. One rule of thumb might be the stud-to-stud nail spacing should be the same as the plywood-to-stud spacing.

Here you can see how a conventional shear wall is built. When shear walls are built on a stepped foundation the framing is different.

The procedure best used with shear walls built on stepped foundations is as follows:

The procedure best used with shear walls built on stepped foundations is as follows:

1) Nail the edges of the tallest shear wall segment 1.5″ apart. This makes the tall segment as stiff as possible.

2) Multiply the height of this wall by 1.5

3) Divide by the shortest wall

4) The result is our allowed distance between nails on the edges of the plywood.

For example. we have two shear wall segments. One is 84” the other is 42”.

The tightest we can nail the edges on the tall wall is a nail every 1.5″.

Multiply tall wall times 1.5

84 x 1.5=126

Divide by short wall

126/42=3

Shorter 42” wall should have 3” nailing on all edges.