In this video you will learn how to attach a shear wall to the floor framing without removing the drywall.

When there is sheet rock on the ceiling, there are two ways to connect the floor to the shear wall. One way is to remove a strip of the sheet rock 12-18 inches wide next to the top of the wall and use conventional shear transfer ties. The other way is to use lag bolts.

Acoustic Ceiling Torn Out for Framing Anchors

![]()

Acoustic Ceiling Torn Out for Framing Anchors.

Here you are looking at someone driving a lag bolt up through the top of the cripple wall and into the floor framing. This is for illustration purposes so that you can see how the lag bolt is driven through the top plates into the floor framing which is normally hidden by sheet rock.

A perfect example of a wall where lag bolts will work as shear transfer ties.

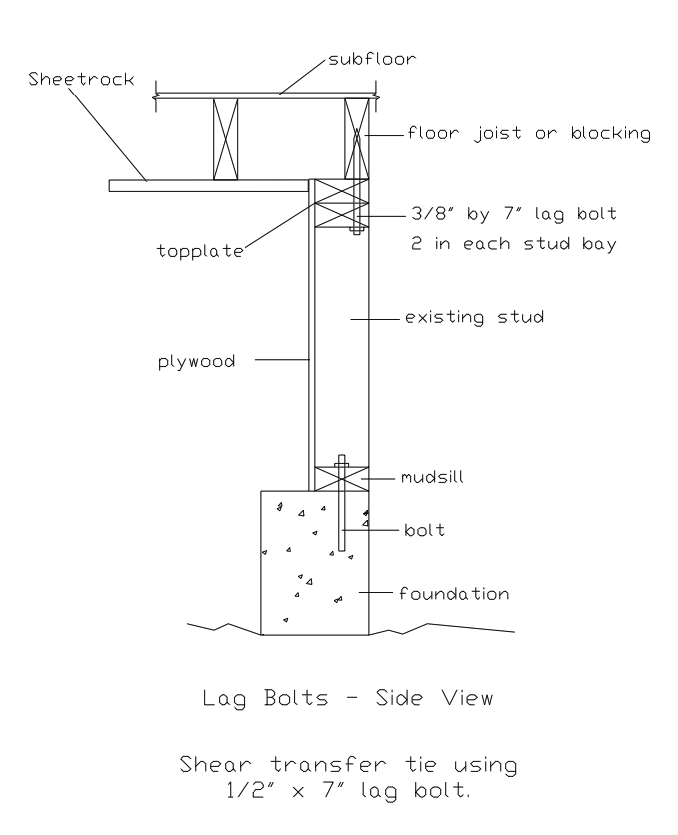

The drawing below shows how a lag bolt can do the same thing as a shear transfer tie without removing the plaster. Here you are looking at it from the end.

How many lag bolts?

If for some reason there is no floor framing above the cripple wall for the lag bolts to bite into, it will be necessary to remove a strip of sheet rock from the as shown here and use conventional shear transfer ties.

Lag bolt strength is defined by the inches of penetration into what is called the “main member.” The main member in this case is the floor joist that the lag bolts are driven into.

According to the table below, any lag bolt that is driven through a 2x that penetrates at least 2″ into the rim joist, can resist 200 lbs of earthquake force. A lag bolt with 1 ½ inches penetration can resist 300 pounds of earthquake force.

However, look at footnote 3 “Loads may be increased for load duration by the building code up to Cd = 1.60. This 1.6 is an earthquake force multiplier such that the values here can all be multiplied by 1.6 and remain legitimate. In this case 1.6 x 200 = 400 lbs.

Here is an example:

Let’s assume, based on this page on plywood science, you have a 10-foot-long shear wall and you have nailed the plywood with 8d common nails 3 inches apart on the edges. This shear wall can therefore resist 5,500 pounds of force.

With an 6-inch lag bolt we will need to go through the 2″ thick lower and 2″ thick upper top plates, which means the lag bolt will penetrate 2 inches into the joist. A lag bolt with 2″ or more penetration gives us 400 pounds of resistance. Divide 5500/400 and we discover we need 13.75 lag bolts for the shear transfer tie component of our shear wall. In this case we round it up to 14 lag bolts.

Here is another example

Edge Distance for SDS Screws

If the edge distance is 1/2″ rather than 5/8″ you must multiply the SDS Screw value by a reduction factor. For example, let’s assume a 1/2″ edge distance creates a reduction factor if 66%. We multiply that by 400# = 264#.

Nailing the bottom and top plates together. The interface where the upper and lower top plate touch is called an “unsecured shear plane” and there is potential slippage here and must be addressed. The way this is done is nailing the two top plates together with 12d common nails that can resist 188# of force each. This connection must equal the shear transfer ties connection. In our example we put in 10 shear transfer ties that can resist 5500# of force. We divide that by 5,500#/188# and we discover we need 30 nails.

12d common nails that can resist 188#. This connection must equal the shear transfer ties connection. In our example we put in 10 lag bolt shear transfer ties that can resist 8700# of force. We divide that by 8,700#/188# and we discover we need 46 nails.

Conclusion

Lag bolts are a far superior way because when they are used it is not necessary to remove the sheet rock from the ceiling, replace the sheet rock, texture it, and paint it to match the sheet rock next to it. Even when this is done by a highly skilled (and expensive) professional, imperfections are always visible, and you can never make the repair completely match.

Most contractors will leave this up to you, which can add considerably to the total job cost.

When hiring a contractor ask them how they intend to attach the shear wall to the floor once they take the sheet rock off the wall. If they tell you lag bolts, you have a professional with experience. If they tell you “I need to tear out part of the ceiling to do it,” you will be facing a future expense with patching the ceiling.